3D concrete printer house

Beckum, Germany

© Peri GmbH

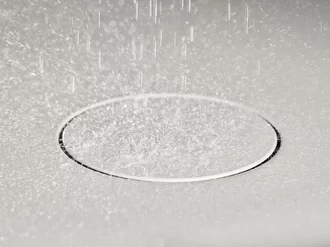

Bathroom of the future:

Germany's first officially approved single-family house built using the 3D concrete printing process is now located in Beckum in Münster. The installation of a Bette bath and two Bette shower trays proves that this is a visionary, quality-driven and sustainable model project. For planners and architects, 3D printing means a high degree of design freedom in the design of buildings. If the technology catches on, they will be able to realise shapes in the future that would only be feasible in conventional construction at great financial expense. The two-storey residential building in Beckum with around 160 square metres of living space was also first created three-dimensionally on the computer before the 3D concrete printer printed everything out with centimetre precision. And that was done in the course of just a few days. How does it work? The print head spits concrete out like cream from a squirt bag. At a speed of up to one metre per second, it moves along its programmed path on a permanently installed metal framework. Layer by layer, the walls of a building grow upwards.

An exciting moment for architects and craftsmen was the insertion of the bath products into the printed form. But not only did the installation of the two BetteFloor shower surfaces into the prefabricated components go smoothly, the BettePool Oval also fitted perfectly into the design of the rounded house wall and the bath apron, which had also been printed from concrete. An experiment that shows:

© Thorsten Thiel/vor-ort-foto.de

© Thorsten Thiel/vor-ort-foto.de

Architecture from the printer can successfully combine well thought-out design and high-quality material with precise technology and modern methods.

With Bette, you could tell that they put their heart and soul into it right from the start. You need that kind of support, otherwise you can't realise such an ambitious project.

Similar references