Interview

The first printed home has a bath by Bette

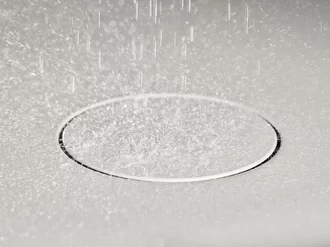

Beckum in Münsterland is now home to Germany's first single-family house built using the 3D concrete printing process. The visionary project features a Bette bath and two Bette shower trays. Architect Alexander Hoffmann and plumber Tobias Leifhelm tell how 3D technology is also changing the planning and construction process in the bathroom.

Mr Hoffmann, Mr Leifhelm, now that you have realised Germany's first printed residential building: Is 3D printing the construction method of the future?

How does 3D printing work exactly? How does the house come out of the printer?

How big is a printer like this?

And the printer nozzle then sprays the concrete like a cream sprayer.

And how long does it take to print a whole house?

In comparison: how long would it take to build a house using conventional construction methods?

What are other advantages?

How does the construction process change in the bathroom?

Why did you choose Bette?

What did you learn from this project?

When will you build the next 3D house?