Press

Let's talk about the folded rim!

Honest materials, straight lines, generous areas, minimal joints, plain colours – puristically designed bathrooms radiate harmony and tranquility, but they are loved by their occupants. Their power and clarity spring from the reduction to the essential, the omission of anything extraneous. However, this also means that the details become more important, as the eye in the minimalist bathroom is not distracted by ornamentation and décor.

One of these details is aesthetic, flush transitions between the materials, for example between the washbasin and furniture or the bath and tiles, wood or natural stone. Differences in height, unevenness or large gaps are particularly noticeable in these places, causing restlessness and disturbing the harmony. At this fine border, skilled craftsmanship differs from standard industrial solutions.

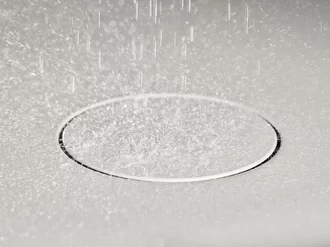

This is why the bathroom specialist Bette made an enormous effort to make the folded rims of its bathroom elements as delicate as possible. With masterful control of the material, plenty of heat and lots of pressure, the Delbrück-based company achieved a slender eight millimetres at this point - a record figure for glazed titanium steel. It ensures that the company's washbasin and exclusive baths appear to integrate seamlessly in the bathroom architecture without the rims protruding at the top when flush-mounted.

Given the robustness of the material, this was not an easy task. It is important to know that the folded rim is created by bending the outer edges of the bath or washbasin, which means that there is at least a double thickness of the material at that point. This is something anyone who has ever shortened a pair of jeans and folded the hem over once or twice before sewing it will be familiar with. On a pair of jeans the effect is deliberate, because on the one hand the bottom of the leg needs to be strong, and on the other it would otherwise obviously look as if it had been shortened.

The outer edges of the bathroom elements are folded to remove the sharpness of the steel and to make it easier to glaze this sensitive area later on, i.e. to cover it in glass. In order to regain a slender shape of the folded steel, 250 tons - equivalent to the weight of 50 elephants - are placed on the robust material for about 40 seconds. Afterwards, the gently rounded edge is glazed with a calm, practised hand with three layers of a special enamel formulation and fused with the titanium steel body at 850 degrees.

The result is quite literally something to behold. Thanks to the graceful outer edges, Bette's bathroom products appear to blend seamlessly in the bathroom environment. The eye glides effortlessly over the surfaces without getting stuck on the material transitions. This results in purist bathrooms with clear shapes and a subtly minimalistic and modern look that encourages body and soul relax.