Press

BetteUltra and minimum support in bathroom prefabrication

With its concept of realising high-quality, individual and design-oriented bathroom systems in large runs, DEBA Badsysteme GmbH from Salzwedel has, according to its own statements, been the market leader in Germany for 20 years now - between 2,500 and 3,000 bathroom units for care, student accommodation, residential construction and hotels leave the company's assembly halls every year. For the McDreams Hotel Ingolstadt, which is scheduled to open in spring 2021, the company is producing turnkey bathroom units in which BetteUltra shower trays with upstand and minimum support from Bette are used.

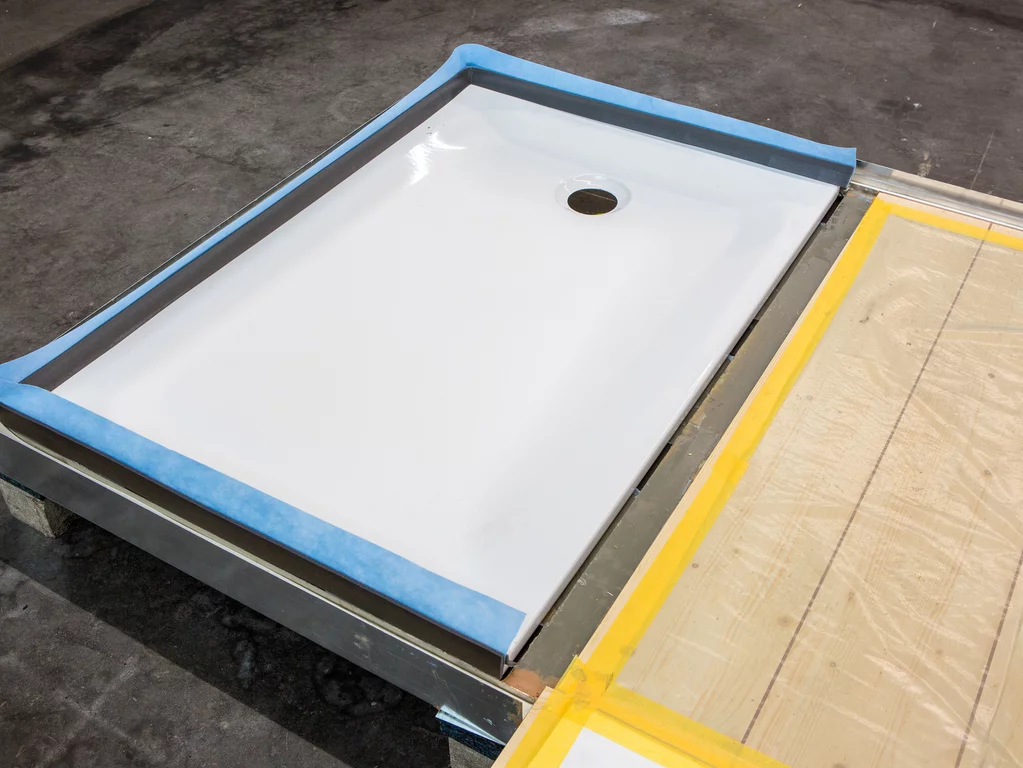

Working with the BetteUpstand was a novelty for the bathroom system manufacturer. As the BetteUltra shower trays with upstand are not simply inserted, but rather constructively integrated into the wall structure, a rethink was necessary in production. "We thought through and planned the design of the shower area with upstand well in advance so that the installation of the bathrooms would run smoothly. Bette supported us in an exemplary manner with technical know-how, documentation and samples," explains Jorg Weinhold, Head of Supply Chain at Deba. All that was needed was to make preparations for the last wall tile to run over the upstand so that the final installation of the bathroom by the plumbers, tilers and fitters could be carried out quickly and easily.

Speed is a decisive criterion in the prefabrication of bathroom systems, as the time schedule, construction sequence and delivery schedules are closely timed. Production must be precisely coordinated with this, and the finished bathroom units must be available almost just-in-time. "We deliver the bathrooms before the ceiling is concreted, we are talking about a time window of about two to three days", says Weinhold, "with Bette has worked smoothly".

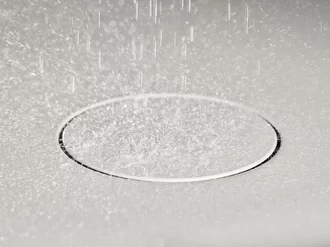

The upstand itself has also proven itself in the eyes of the bathroom system manufacturer: "This is a beautiful solution, an optical highlight! Doing without silicon joints on the wall side saves the future operator additional maintenance work and pays off in terms of protection against moisture penetration, which is already extremely high with our multi-layer sealed bathroom systems due to their design". All that remains visible to the user is a wall-side upstand made of glazed titanium steel, which disappears under the wall covering and is much more robust and easier to clean than a silicone joint. In general, the durable glazed titanium steel is the material of choice for the bathroom system specialist when shower trays are used; plastic or cast mineral are rarely chosen...

Also new for the company was the installation of the BetteUltra shower trays used, using Bette's minimum support. It also impressed with its simple and time-saving processing. Jorg Weinhold: "The tub support is a clever idea, it was delivered to us by Bette already pre-assembled with the shower tray. This meant that the tub could be installed in practically a single step - finished! Since the shower tray is glued to the bathroom floor with the help of the minimum tray support, it is also securely fixed, because nothing must come loose when the shower tray is transported by truck to Ingolstadt and the bath units are inserted into the McDreams Hotel building with the crane.

Address:

DEBA Bathroom Systems GmbH

Gardelegener Str. 18

D-29410 Saltwedel